HyFilDrain: Development of energy-efficient coalescence filter media for the compression of hydrogen

The increased future demand for hydrogen to cover energy requirements using environmentally friendly resources and the worldwide availability required for this will bring the transport of hydrogen via pipelines to the center of attention. Due to long transport routes, the hydrogen must be regularly compressed to its initial pressure. Appropriate compressors are required for compression, which must be equipped with coalescence filters to ensure the purity of the hydrogen during transport. The project is concerned with the development and realization of the production of coalescence filter media, which are manufactured using a foam application process. A targeted design of the filter media enables a reduction in pressure loss and thus an enormous CO2 saving potential.

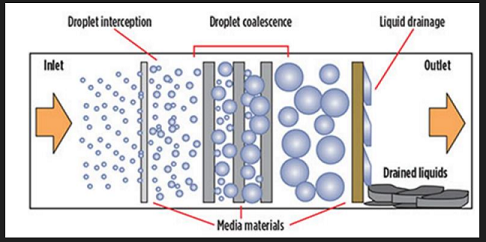

Figure 1: Schematic representation of the processes on a coalescence filter

The university's sub-project involves the modelling and simulation of filter systems based on machine learning approaches and different CFD methods such as Smoothed-Particle-Hydrodynamics (SPH) and Volume-of-Fluid (VoF). Using suitable co-simulations, models can be calculated and coupled on different scales, from the size of the filter fibres to the overall system. The validated models allow the calculation of complex filter structures and thus an increase in the efficiency of the filter media, which leads to a reduction in pressure loss and therefore to a reduction in CO2.

The research project is being carried out in cooperation with the company Hollingsworth&Vose GmbH, which is conducting the development and experimental tests on the filter media.

This project is funded by the BMWK and Projektträger Jülich under the funding code 03EI3082B within the "Förderbereich: Sektorenkopplung und Wasserstofftechnologie".